Semiconductor Testing Solutions

Our semiconductor tester systems combine functional, parametric, reliability, and accelerated stress testing to detect defects early, reduce field failures and warranty risk, and accelerate time to market while meeting strict industry qualification standards.

Our custom semiconductor testers are designed to test & measure 32 – 1024 devices. These systems include temperature cycle tests, which involve subjecting samples to varying extreme temperatures in a controlled environment to evaluate material response to thermal stress.

Burn-In Testing

Our burn-in testing helps in detecting early failures and defects in your semiconductors. This process ensures that only reliable devices proceed to the next stages of the manufacturing or assembly process.

Additionally, high temperature operating life (HTOL) testing evaluates the lifespan and failure points of devices under extended exposure to high temperatures and electrical stress, providing critical insights into design robustness and real-world effectiveness.

Semiconductor Device Reliability Testing

Rigorous reliability testing is essential to predicting the lifespan and identifying weaknesses in your semiconductor package.

This includes identifying failure modes by pushing devices to their limits to uncover intrinsic reliability issues.

Contact us today for your customized quote.

Stress Testing of Components

Our semiconductor tester system employs highly accelerated stress tests (HAST) to evaluate integrated circuits by simulating extreme conditions.

Additionally, we utilize intermittent operating life tests (IOL) to reveal reliability issues by cycling the device on and off, simulating the thermal and mechanical stresses encountered in real-world conditions.

Comprehensive Semiconductor & Passive Component Test Capabilities

From integrated circuits and power semiconductors to optoelectronic devices and critical passive components, our semiconductor tester solutions enable OEMs, manufacturers and R&D teams to validate quality, reduce failure risk, and meet industry qualification standards.

Search the table below to find your component types, package formats, and common semiconductor testing focus areas supported by our advanced test equipment.

| Component Category | Package / Component Type | Typical Applications | Common Test Focus |

|---|---|---|---|

| Integrated Circuits (ICs) | DIP / PDIP | Legacy electronics, prototyping, control systems | Functional testing, burn-in, parametric verification |

| Integrated Circuits (ICs) | SOIC, TSSOP | Consumer, industrial control, analog/digital ICs | Electrical performance, aging, temperature cycling |

| Integrated Circuits (ICs) | QFN, QFP | High-density electronics, automotive, telecom | Thermal stress, signal integrity, lifetime testing |

| Integrated Circuits (ICs) | BGA, LGA | Processors, memory, high-speed devices | Reliability, solder joint stress, thermal cycling |

| Power Semiconductors | TO-220, TO-247 | Power supplies, motor drives, inverters | High-current stress, thermal performance, burn-in |

| Power Semiconductors | TO-263 (D2PAK), SOT packages | Compact power electronics | Load cycling, efficiency, heat dissipation |

| Optoelectronics | TO-Can (sealed/windowed) | Laser diodes, photodiodes, sensors | Optical output stability, temperature stress |

| Optoelectronics | Butterfly packages | Telecom lasers, precision optics | TEC control testing, lifetime, modulation |

| Optoelectronics | C-Mount | High-power laser systems | Thermal management, power stability |

| Optoelectronics | Chip-on-Submount (CoS) | Bare die laser & sensor assemblies | Die-level reliability, thermal aging |

| Passive Components | Resistors (SMD, through-hole, power) | Signal control, current limiting | Drift, overload, thermal aging |

| Passive Components | Capacitors (ceramic, electrolytic, tantalum, film) | Power filtering, energy storage | ESR, leakage, lifetime, humidity stress |

| Passive Components | Inductors & transformers | Power conversion, RF circuits | Saturation, heating, insulation testing |

| Passive Components | Crystals & oscillators | Timing & frequency control | Frequency stability, aging, thermal drift |

| Interconnect Components | Connectors & sockets | System integration | Mechanical stress, continuity, thermal cycling |

Industries We Support

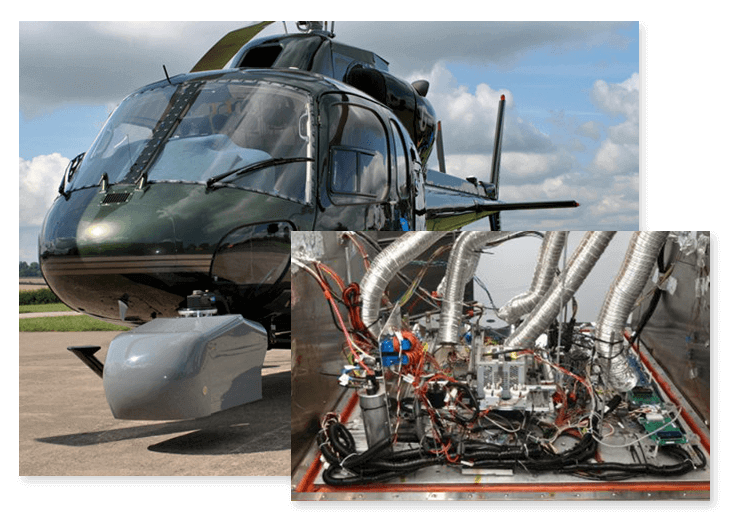

Aerospace & Defense

Semiconductor testing for aerospace and defense applications, covering pulsed optoelectronic devices, NIR photodetectors, power electronics, and high-reliability integrated circuits.

Telecommunication

Semiconductor testing across optoelectronics, high-speed ICs, power devices, and passive components supporting data centers, fiber-optic links, and long-haul telecommunications networks.

Medical & Health

High-reliability semiconductor testing supporting medical devices, covering optoelectronics, advanced IC packages, power electronics, and passive components used in imaging, laser therapy, monitoring, and clinical treatment systems.

Automotive

Semiconductor and electronic component testing for automotive applications, covering sensing devices, integrated circuits, power semiconductors, and passive components used in ADAS, LIDAR, EV systems, and vehicle electronics.

Research & Development

Semiconductor testing for research and development across optoelectronics, ICs, power devices, and passive components for scientific and advanced technology applications.

Security and Surveillance

Semiconductor and electronic component testing for security and surveillance systems, covering sensing devices, integrated circuits, power semiconductors, and passive components used in imaging, facial recognition, and monitoring technologies.

Semiconductor Tester Software

Semiconductor reliability testing is a critical process that ensures device performance, durability, and long-term quality across demanding applications. It requires precise test design, controlled stress conditions, and intelligent data analysis to identify early-life failures and long-term reliability risks.

Our semiconductor tester software supports advanced reliability workflows, including failure analysis, board-level reliability assessment, and accelerated life testing (ALT). By subjecting devices to elevated temperature, voltage, and environmental stress, ALT enables faster identification of failure mechanisms and lifetime performance limits.

Our automated test equipment software integrates robust quality monitoring and real-time data evaluation across every stage of the testing process. This allows manufacturers to detect defects early, reduce reliability risk, and improve overall product yield.

We specialize in semiconductor reliability test systems for packaged devices, including laser diodes, photodiodes, integrated circuits, power semiconductors, and passive components. Our platforms focus on precision device-level testing rather than wafer-level probing, delivering accurate, repeatable results for qualification, production, and advanced research environments.

Frequently Asked Questions

Do you perform wafer testing?

Our ATE semiconductor testing equipment do not include wafer testing or wafer test procedures. Instead, we are dedicated to the specialized testing of laser diodes and photodiodes.

Our focus is on ensuring the highest quality and performance of these optoelectronic components through rigorous testing methodologies tailored to the specific characteristics of laser diodes and photodiodes.

What types of semiconductor testing do you perform?

- Package Testing: Testing the semiconductor device after it has been packaged.

- Burn-In Testing: Running the device at elevated temperatures and voltages to catch early failures.

- Parametric Testing: Measuring electrical parameters to ensure they meet specifications.

- Functional Testing: Verifying that the device performs its intended functions correctly.

Why are Semiconductor Testers Important?

Ensuring Quality and Reliability

Semiconductor testers are essential for maintaining the quality and reliability of electronic components and devices. It helps identify and eliminate defects early in the manufacturing process, ensuring that only high-quality products reach consumers. This is particularly important for the performance and reliability of electronic products used in critical applications such as aerospace and healthcare.

Meeting Industry Standards and Compliance

Semiconductors must adhere to strict industry standards and regulatory requirements. Testing ensures that each device meets these standards, which is vital in industries like automotive and medical, where the consequences of device failure can be severe.

Enhancing Performance

Performance testing verifies that semiconductor devices function correctly under various conditions, ensuring they meet electrical and functional specifications. High-performance standards are particularly important in fields like telecommunications, where devices must handle high data rates and demanding operational environments.

What kind of reliability testing do you do?

Reliability testing for extreme environments involves subjecting semiconductor devices to harsh conditions such as extreme temperatures, high humidity, and other environmental stressors.

This type of testing is designed to simulate real-world usage scenarios where devices may be exposed to challenging conditions. By evaluating how semiconductor devices perform under these extreme conditions, reliability testing ensures that they can maintain their functionality and reliability in demanding environments.

This is particularly important for applications in aerospace, defense, and other industries where device reliability is critical.

What is reliability testing?

Reliability testing is a crucial process in the development and production of semiconductor devices. It ensures that the devices meet the required standards of performance, quality, and reliability.

There are several types of reliability testing, each with its own unique characteristics and objectives..

Types of Semiconductor Reliability Testing

Accelerated Life Testing (ALT)

Accelerated life testing (ALT) subjects semiconductor devices to accelerated stress conditions to simulate the effects of time and usage.

By exposing devices to elevated temperatures, increased voltages, and other stress factors, ALT helps predict the long-term reliability and lifespan of the devices.

This type of reliability testing is invaluable for identifying potential issues and defects that could lead to failures, thereby enhancing the overall performance and durability of semiconductor products.

What equipment is used in semiconductor testing?

Each piece of equipment plays a specific role in the testing process.

What are common defects detected during semiconductor testing?

Common defects include electrical shorts, open circuits, incorrect doping levels, and various parametric deviations from the specified norms.

These defects can affect the performance, reliability, and longevity of semiconductor devices.

What is a semiconductor tester?

A semiconductor tester is a specialized piece of equipment used to evaluate the functionality, performance, and reliability of semiconductors. These testers are crucial in the semiconductor manufacturing process to ensure that the devices meet specified standards and are free of defects before they are used in electronic products.

These defects can affect the performance, reliability, and longevity of semiconductors.

Key Functions of Semiconductor Testers

- Defect Detection:

- Semiconductor testers identify defects in semiconductor packages. Early detection of defects is critical to preventing faulty devices from reaching the market.

- Performance Verification:

- These testers verify the electrical and functional performance of semiconductors, ensuring they meet required specifications.

- Reliability Testing:

- Semiconductor testers conduct reliability tests to evaluate how devices perform under various conditions, including temperature extremes, voltage variations, and prolonged use.

For more information about our semiconductor reliability testing solutions, please request a quote.

Our application engineers are ready to assist you with your testing needs and ensure that your semiconductor devices meet the highest standards of quality and performance.

HEAD OFFICE

Electron Test Equipment Limited

5a Whytecliffe Road South, Purley, CR8 2AY, England

Phone: + 44 1293 904 001

E-mail:

moc.tsetnortcele@su-tcatnoc